Description

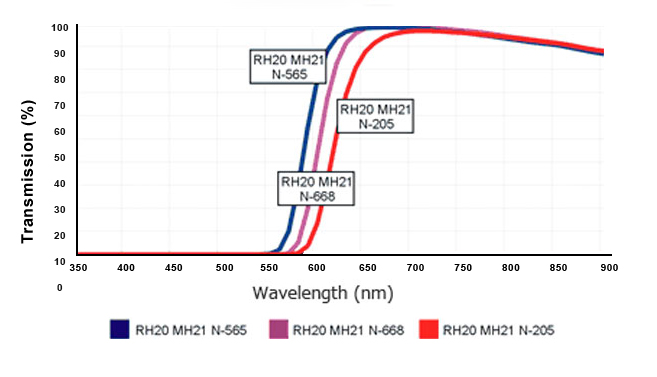

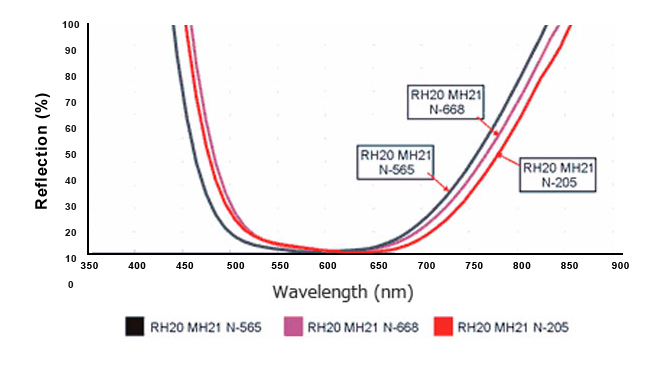

The AR Coat Filter is designed to maximize the transmission of 630 – 670nm lasers. Scratch-resistant, anti-reflection, and anti-smudge coatings are available.

- Excellent transmission

- Excellent optical characteristics

- Excellent surface hardness

- Excellent smudge resistance

MAXIMUM AVAILABLE SIZE – With Anti-Reflection Coating 290mm x 360mm. Without Anti-Reflection Coating 400mm x 550mm.

THICKNESS – 0.5, 0.8, 1.0. 1.5, 2.0, 2.5, 3.0, 4.0 and 5.0mm. Please contact us if you require other thickness.

MACHINING / PRINTING – Available to customer specification.

COLORS – Available in clear and many colors.

| PHYSICAL PROPERTIES |

| PROPERTY |

METHOD |

UNIT |

Value |

| Specific Gravity |

ASTM D-792 |

|

1.19 |

| Elongation |

ASTM D-638 |

% |

5 |

| Flexural Rupture Strength |

ASTM D-790 |

kg/cm2 |

800 |

| Heat Distortion Temperature |

ASTM D-648 |

ºC |

110 |

| Maximum recommended continuous temperature |

2 |

ºC |

80 |

| Available with higher temperature ratings on request, 90-95ºC |

| Coefficient of Thermal Expansion |

ASTM D-696 |

cm/cm/ºC |

7 x 10-5 |

| Heat Resistance |

80ºC x 100hr |

|

No Change |

| Cold Resistance |

-40ºC x 100hr |

|

No Change |

| Humidity Resistance |

40ºC x 90% x 100hr |

|

No Change |

| Thermal Cycle |

-40ºC <> 80ºC

(10 cycles) |

|

No Change |

| Pencil Hardness |

|

|

6H – 8H |

| Shed Water (Touch Angle) |

|

|

114º |

| CHEMICAL |

| Sodium Carbonate |

|

|

Dissolved |

| Soap Aqua Solution |

|

|

No Change |

| Sulfuric Acid |

|

|

Dissolved |

| Isopropyl Alcohol |

|

|

No Change |

| Water |

|

|

No Change |

* Value provided cannot be guaranteed in your application due to circumstances beyond our control.

Leave a Reply